In today's technological era, the role of electrical machines cannot be underestimated. One such ubiquitous device is the DC motor, which is widely used in various applications, from household appliances to industrial machinery. In this comprehensive blog, we will delve into the workings of a DC motor and highlight its importance in our everyday lives.

What is a DC Motor?

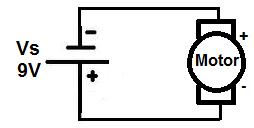

A DC motor, short for Direct Current motor, is a rotary electrical machine that converts direct current electrical energy into mechanical energy. Unlike its counterpart, the AC (Alternating Current) motor, a DC motor operates solely on direct current. The key principle behind its operation lies in the forces generated by magnetic fields.

Working Principle:

To understand the working principle of a DC motor, we need to explore its internal mechanism. Generally, all types of DC motors have either an electromechanical or electronic mechanism to periodically change the direction of current flow within the motor. This process allows for the generation of rotational motion.

The foundation of a DC motor lies in its basic components: the stator, rotor, and commutator. The stator comprises the stationary part of the motor and houses the field windings that create the magnetic field. On the other hand, the rotor consists of the armature, which contains the current-carrying conductors.

When a current flows through the windings of the stator, a magnetic field is produced. This magnetic field interacts with the armature's current-carrying conductors, resulting in a force that rotates the armature. The commutator, an essential component, periodically alternates the direction of the current flow in the armature conductors. By changing the direction of current flow, the motor ensures a continuous rotational movement.

Types of DC Motors:

DC motors come in various types, each with its specific characteristics and applications. Let's take a closer look at some of the most common types:

1. Brushed DC Motors:

Brushed DC motors utilize brushes and a commutator to transfer current to the rotor's armature. These motors are widely used due to their simplicity, cost-effectiveness, and the ability to control speed and torque. However, they require periodic maintenance due to wear and tear of the brushes.

2. Brushless DC Motors:

Brushless DC motors, as the name suggests, eliminate the need for brushes and commutators. Instead, they rely on electronic controllers to switch current flow. These motors offer improved efficiency, higher power-to-weight ratio, and longer lifespan. Their widespread application can be seen in drones, electric vehicles, and industrial automation.

Applications of DC Motors:

DC motors find extensive use in a wide variety of applications owing to their versatility and reliability. Some common areas where these motors are employed include:

1. Robotics and Automation:

DC motors form the backbone of robotic systems, allowing them to perform precise movements and actions. From assembly line robots to humanoid robots, DC motors drive the mechanical operation of these complex machines.

2. Household Appliances:

In many of our daily used appliances like vacuum cleaners, mixers, fans, and washing machines, DC motors operate behind the scenes to provide the required rotational movement. Their efficiency and quiet operation make them ideal for such applications.

3. Automotive Industry:

The automotive industry relies heavily on DC motors for numerous functions. From powering the windshield wipers, electric windows, and power seats to driving the cooling fans and steering systems, these motors enhance the overall performance and functionality of vehicles.

4. Renewable Energy Generation:

DC generators play a vital role in renewable energy systems, such as wind turbines and solar panels. They convert the captured energy into usable electricity for homes, businesses, and industries.

5. Industrial Machinery:

DC motors are extensively used in a wide range of industrial machinery, including conveyor systems, pumps, compressors, and manufacturing equipment. Their ability to provide precise control over speed and torque makes them highly suitable for these applications.

In conclusion, DC motors are an integral part of our modern society. Their ability to convert electrical energy into mechanical energy, combined with their versatility and reliability, makes them indispensable in various fields. From household appliances to industrial machinery, these motors continue to play a crucial role in powering our everyday lives. As technology evolves, it is certain that DC motors will continue to advance, bringing forth new applications and opportunities.